C1D1 Extraction Labs

Our modular Prefabricated UL Certified C1D1 Extraction Labs and C1D2 labs are the perfect solution to meet your indoor Extraction needs. At Podtronix, we design, manufacture, and install.

C1D1 Extraction PODs

Podtronix builds UL Certified C1D1 Extraction lab PODs and C1D2 labs, safe and convenient solutions for indoor or outdoor extraction requirements. Built with a 14-gauge steel ISO shipping container.

Full Facility Build Outs

Our prefabricated modular enclosures can be a time saving and cost-effective alternative to hiring a general contractor, disrupting ongoing operations, and navigating the difficult permitting process.

Grow Rooms & Pods

We offer grow rooms and PODs designed to fit your needs, prefabricated rooms and container based grow pods. The only way to get awesome grow result is by having full control over your grow environment.

Extraction Lab Manufacturer Serving the US & Canada

C1D1 & C1D2 Explosion Proof Extraction Labs and Enclosures

We build Prefabricated UL Certified C1D1 Extraction Labs, Prefabricated UL Certified C1D2 Extraction Labs, non-classified processing labs, and post-processing enclosures for the US and Canada. We also build everything in a shipping container-based UL-certified POD version.

Engineered for Safety, Designed for Success, and Certified by UL.

Podtronix C1D1 Extraction Labs and C1D2 Extraction Labs are available in either standard sizes or custom designed to fit almost any facility layout. Our entire product line is engineered and constructed adhering to the highest standards of safety and quality, and certified through extensive third party testing and review.

Our Certifications

All Podtronix products have been thoroughly reviewed and tested, and have been awarded the following certifications:

- Underwriters Laboratories (UL, ULc – 1389)

- PSI – Peer Reviewed

- PRV – Peer Reviewed

Our Standards

All of our products meet or exceed the following national safety and fire standards:

- International Fire Code (IFC)

- California Fire Code (CFC)

- National Fire Protection Assn. Code 1 (NFPA 1)

- National Fire Protection Assn. Code 33 (NFPA 33)

- National Fire Protection Assn. Code 70 (NFPA 70)

- International Mechanical Code (IMC)

- Occupational Safety Hazards Assn. (OSHA)

Enhanced Safety

For plant oil extraction, there are several methods for extracting oil, with most involving the use of flammable solvents. For this reason, the extraction process can pose significant health and safety hazards to your personnel. As a result, plant oil extraction operations may be subjected to a higher level of scrutiny by local building and fire inspectors.

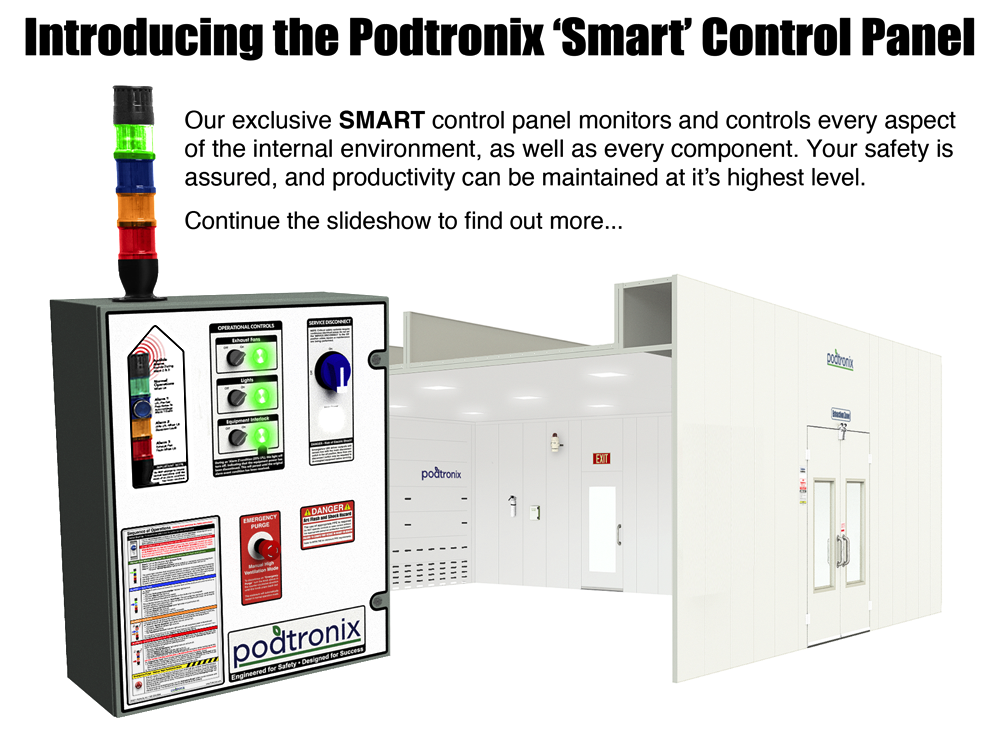

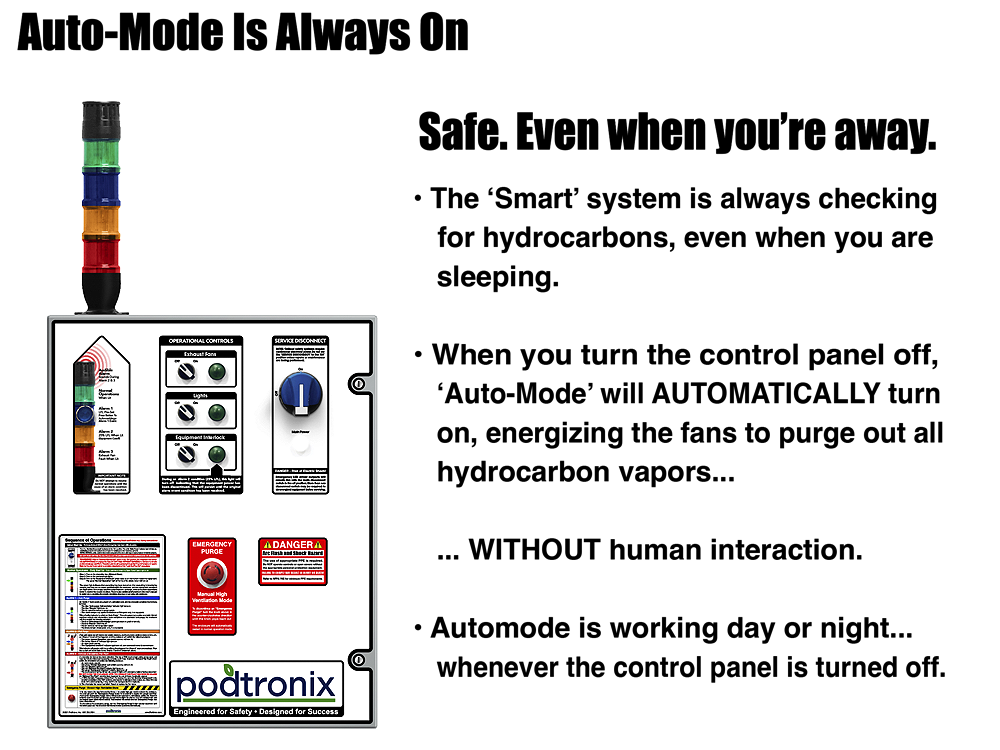

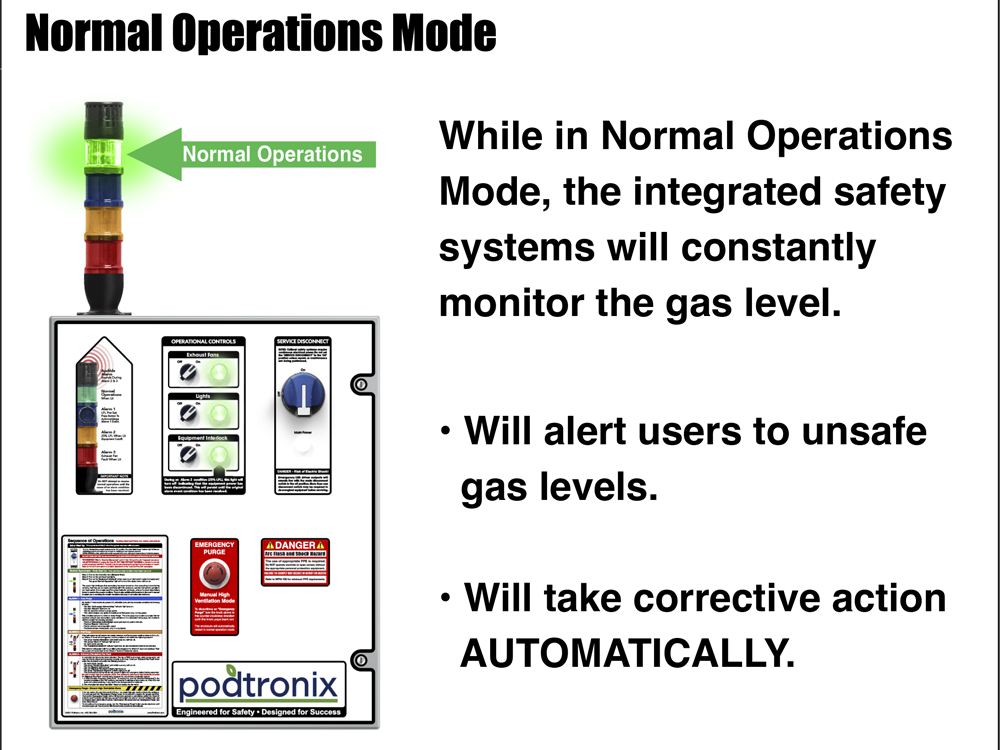

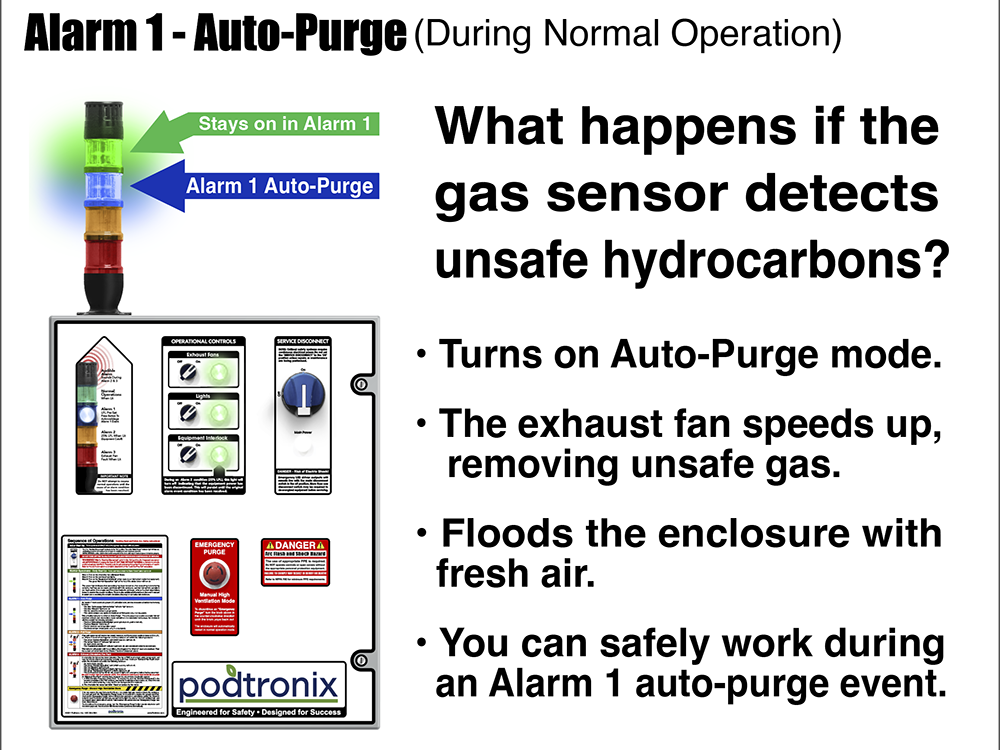

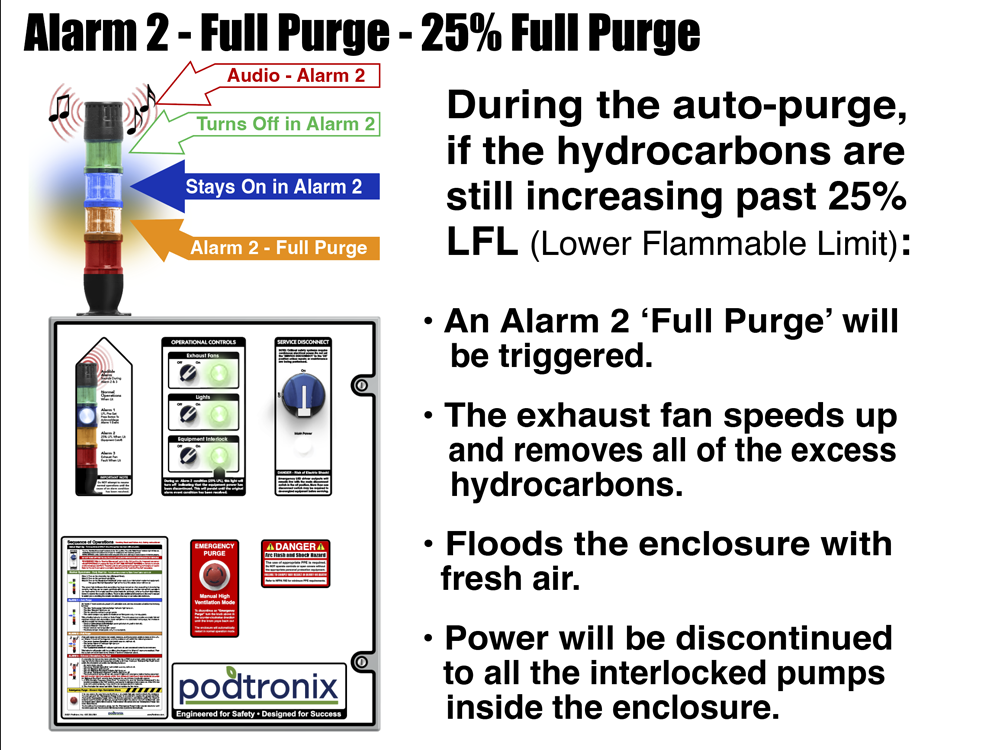

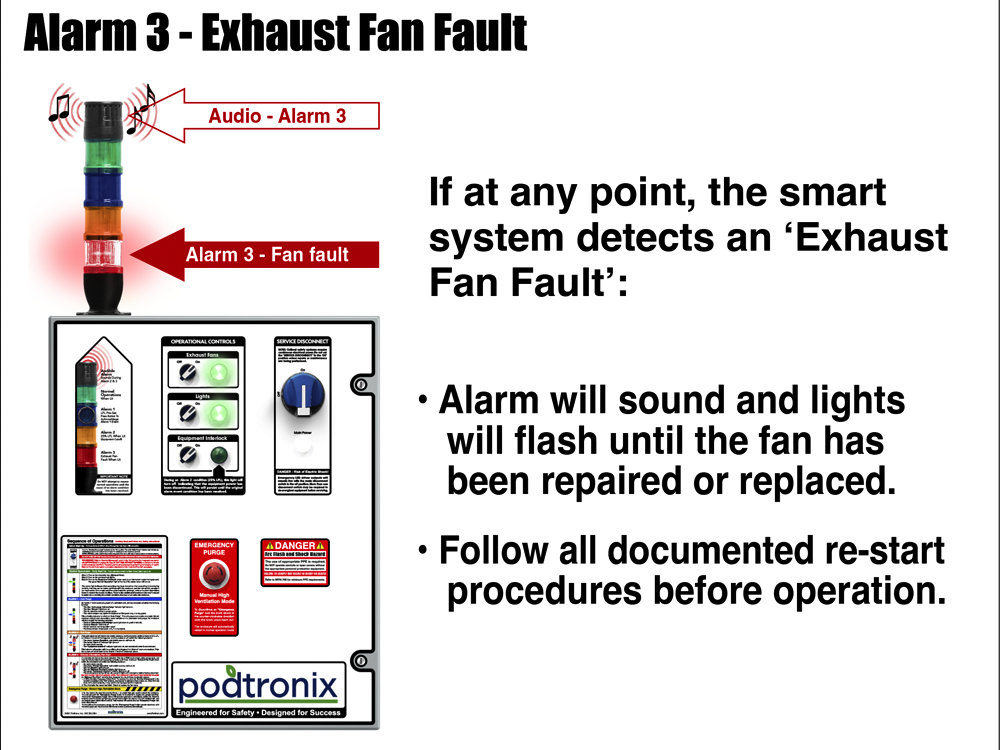

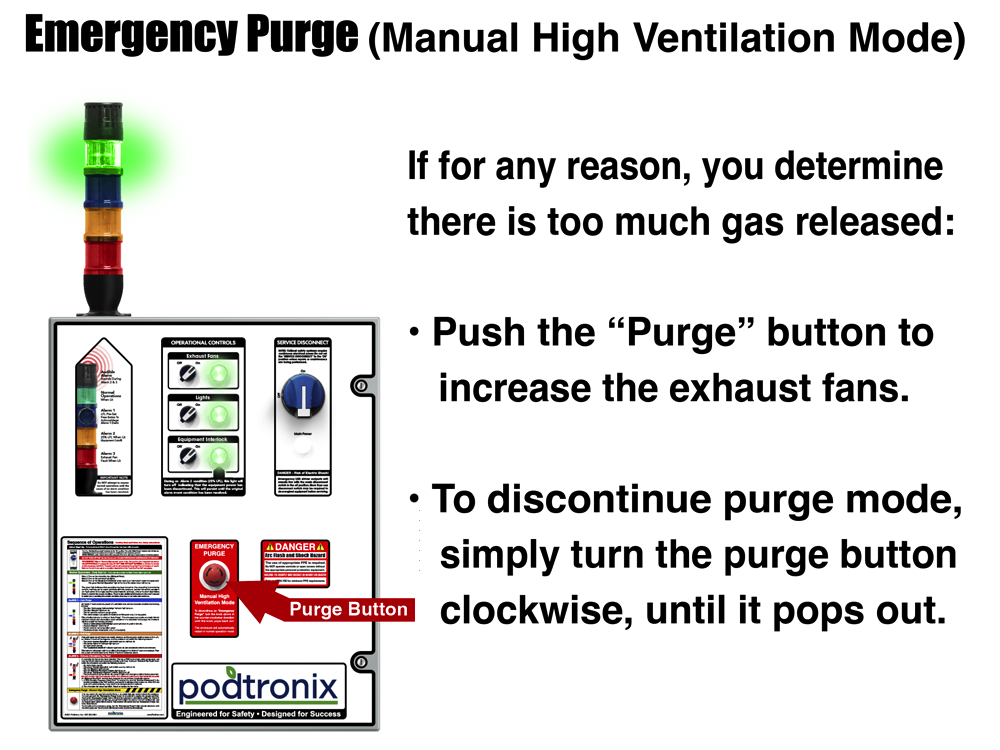

At Podtronix, your safety is our highest priority. Our well-designed extraction enclosures include controlled ventilation, early-detection warning systems that respond automatically, and various code-compliant electrical fixtures and fittings. These are necessary measures, designed to minimize the potential for hazardous conditions to occur, while maximizing personnel safety during the entire production cycle.

Our team will work with you to determine the applicable Class, Division and Zone requirements for your operation and local regulations unique to your jurisdiction. At Podtronix, we understand how to design and build code compliant extraction labs, and how keep your personnel and business safe.

C1D1 vs. C1D2 – What are the Differences?

North American classifications are broken down into classes, divisions, groups, and temperature codes.

Class I, Division 1 – Locations or zones where flammable gases may exist under normal operating conditions and during maintenance or repair events.

Class I, Division 2 – Locations or zones where flammable may exist under accidental or unusual conditions in close proximity to Class I, Division I locations.

Classifications

Class 1 – Flammable vapors or gases; further divided into Groups A-D.

Class 2 – Combustible or electrically conductive dust is present; further divided into Groups E-G.

Class 3 – Fibers and flyings; this is a singular designation and is not subdivided into Groups.

Divisions

The divisions define when hazards are likely to be present:

Division 1 – Hazardous materials are present during normal operating conditions, and hazardous conditions are expected to exist all or most of the time.

Division 2 – Hazardous materials are present in abnormal conditions, such as system or container failures, leaks or ruptures. Hazardous conditions are not expected to always exist, only under unusual conditions.

Our Design Process

Engineered to Exacting Standards

STEP 1

STEP 2

STEP 3

STEP 4

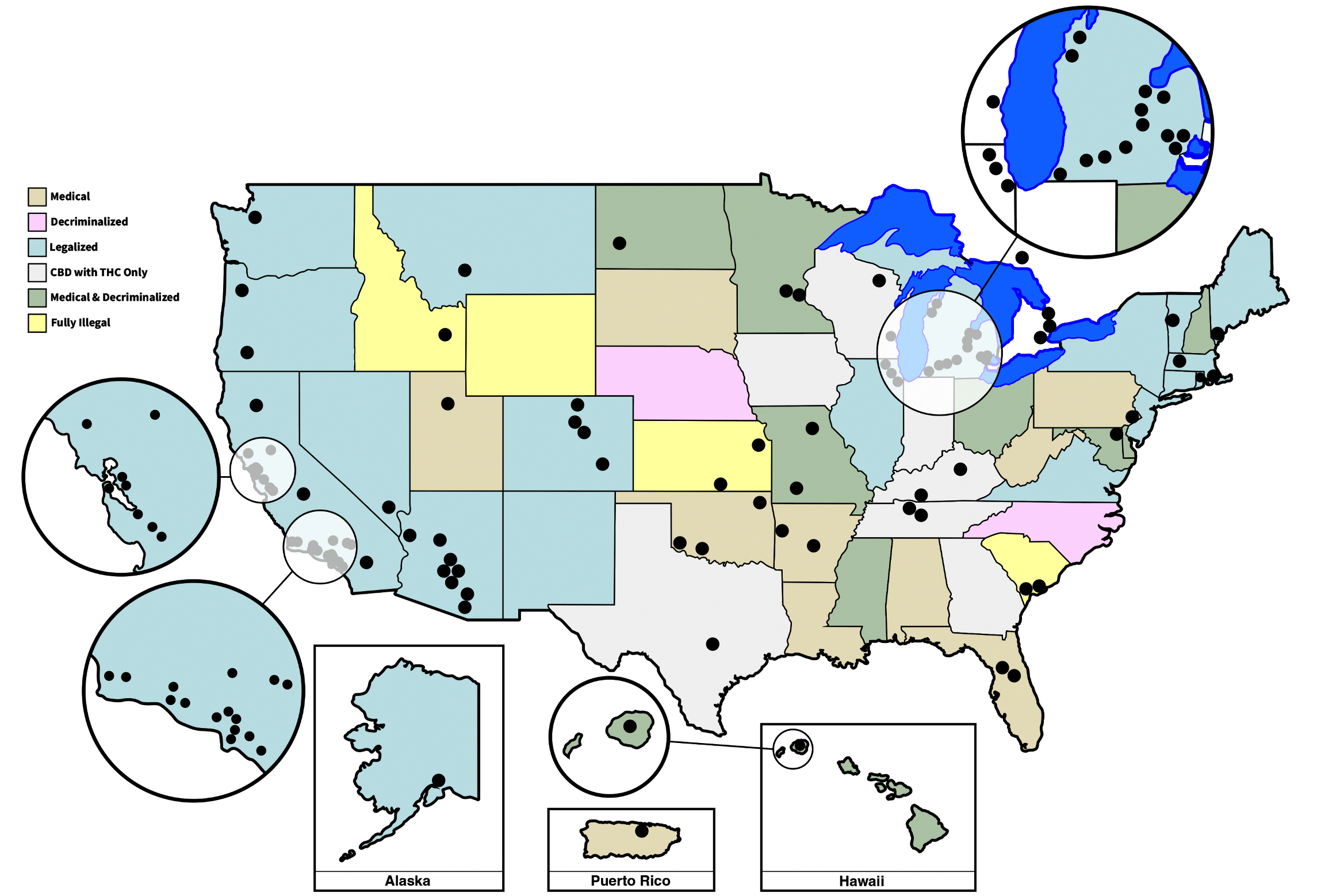

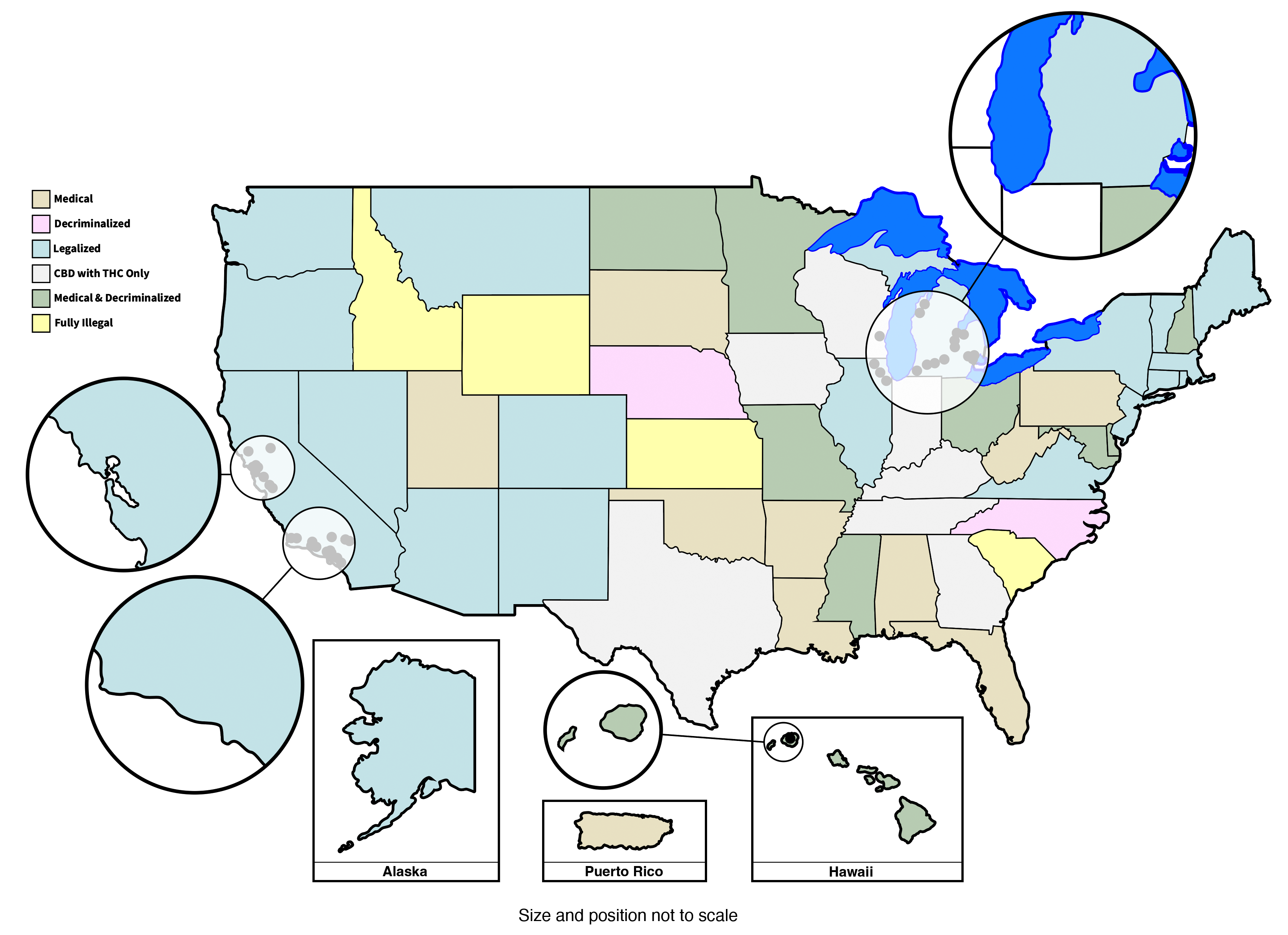

Podtronix Has Completed Installations Across the US and Canada

Podtronix Has Completed Installations Across the US and Canada

Mouse over a dot to see the name of the installation city

Philadelphia, PA

Hazel Park, MI

Earleville, MD

Warren, MI

Keego Harbor, MI

Traverse, MI

Manistee, MI

Vassar, MI

Bay City, MI

Chesaning, MI

Corunna, MI

Eaton Rapids, MI

Battle Creek, MI

Kalamazoo, MI

New Buffalo, MI

Chicago, IL

Hoffman Estates, IL

Cary, IL

Grafton, WI

Lively, ON

Burlington, ON

Toronto, ON

Richmond Hill, ON

Providence, RI

Eustis, FL

Ocala, FL

Kauai, HI

Dorado, PR

Palmer, AK

Santa Rosa, CA

Sacramento, CA

San Francisco, CA

San Jose, CA

Alameda, CA

Oakland, CA

Gilroy, CA

Hollister, CA

Lompoc, CA

Buellton, CA

Ojai, CA

Ventura, CA

Camarillo, CA

Culver City, CA

Los Angeles, CA

Cudahy, CA

Long Beach, CA

Bellflower, CA

Santa Ana, CA

San Jaun Capistrano, CA

Lancaster, CA

Adelanto, CA

Apple Valley, CA

Anderson, CA

Fresno, CA

Palm Desert, CA

White City, OR

Gervais, OR

Maltby, WA

Las Vegas, NV

West Valley City, UT

Idaho Falls, ID

Belgrade, MT

Dickinson, ND

Berthoud, CO

Denver, CO

Centennial, CO

Ordway, CO

Fort Mojave, AZ

Chino Valley, AZ

Scottdale, AZ

Phoenix, AZ

Gilbert, AZ

Casa Grande, AZ

Tucson, AZ

Amado, AZ

Austin, TX

Hollis, OK

Lawton, OK

Big Cabin, OK

Wellington, KS

Middleton, VT

East Wareham, MA

Northampton, MA

Berwick, ME

Lawrence, KS

Springfield, MO

Macon, MO

Crandon, WI

St. Paul, MN

Minneapolis, MN

Little Rock, AR

Fort Smith, AR

Springfield, TN

Nashville, TN

Franklin, KY

Lexington, KY

Seabrook Island, SC

Hilton Head Island, SC

Source: www.disa.com

Engineered for Safety, Designed for Success, Certified by UL.

Trust in Podtronix – Expertly Manufactured Labs and Products.

Check Out Our Instagram Feed

We’re posting new content all the time! Videos, Images, and Articles that you want to see.